AKKI-KS

Project description:

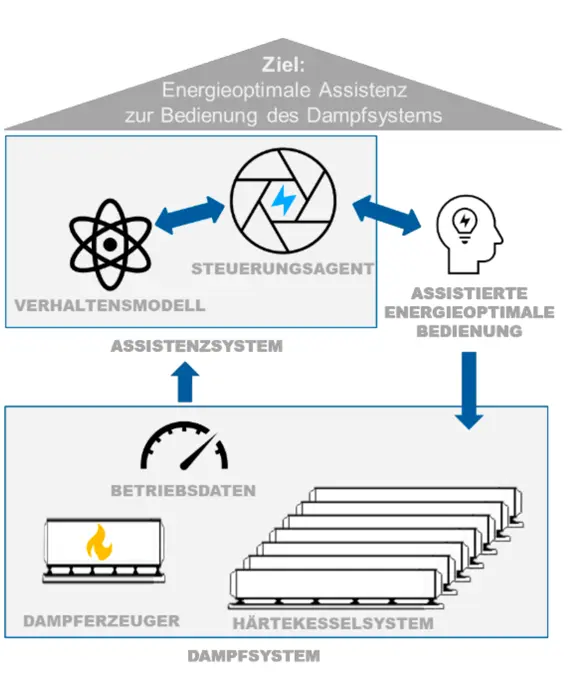

The implementation of the calcium silicate brick (CSB) roadmap requires, among other things, measures in the area of digitalization. It is possible to reduce energy consumption and CO2 emissions by optimizing the operation of autoclave systems. At the heart of the autoclaving process in every CSB plant is the steam system. In most CSB plants, the system technology and controls are similar in principle. However, different plant details and process specifics result in a plant-specific behavior of the steam system. Due to the high process complexity and system dynamics - particularly in the case of transfer processes - fully algorithmic modeling can only be achieved with a great deal of experimental effort. As a result, the correct operating parameters for the systems can only be estimated from empirical values. Unfortunately, energy efficiency is often sacrificed in favor of throughput. This research project therefore aims to use artificial intelligence to explore a less complex method for achieving energy-optimized operation of autoclave systems. To this end, AI software is to learn the plant-specific behavior of the steam systems from available production data. An “AI agent” will be trained, which will then make recommendations for energy-optimized and process-safe system operation during operation.

Project Objectives:

The aim of the project is to create a solution that enables producers to save energy without capital-intensive systems or system expansions or loss of productivity. The end result is software for the individual plant that supports autoclave operation in real time. In addition to predicting actual hardening times, recommendations are given for energy-optimized and process-safe operation of the hardening process. If successful, the CSB plant can save energy and CO2 during autoclaving without any loss of productivity. A formalized process allows easy transfer to other plants. The transfer takes place via several packages of measures (seminars, consulting, specialist publications, conferences and congresses, etc.).

Projekt Partner

Beteiligte Partner:

Forschungsvereinigung Kalk-Sand e.V. (FVKS), Technische Hochschule Ingolstadt (THI), Lehrstuhl für Automatisierungstechnik und Produktionssystemantik (FAPS) der Friedrich-Alexander-Universität Erlangen Nürnberg

Assoziierte Partner:

Cirkel GmbH & Co. KG, Hessisches Baustoffwerk Dr. Blasberg GmbH & Co. KG, Höltinghausener Industriewerke GmbH, Kalksandsteinwerke Schencking GmbH & Co. KG, Kalksandsteinwerk Wemding, Küttner Automation GmbH, Masa GmbH, Schlamann Kalksandsteinwerk GmbH, SCHOLZ Maschinenbau GmbH & Co. KG, Wüseke Baustoffwerke GmbH, Zapfwerke GmbH & Co. KG, HANSA Baustoffwerke Parchim GmbH & Co. KG

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)