Drop Tower

The drop tower is used to investigate the energy absorption behaviour of materials, construction methods, components and structures. The basic function of the drop tower is to transport a test specimen or a defined weight attached to a ram to a height level, to release it there in a controlled manner and to drop it along a linear guide onto a test specimen or impact surface. The resulting short-term impact makes it possible to assess how energy is absorbed by materials, designs, components and structures in the event of a crash and which (low and high frequency) crash signals are generated. The system is suitable for impact tests on plastics, composites and various other materials.

Objectives and Ideas

The basic function of the drop tower is to transport a test specimen or a defined weight attached to a ram to a height level, to release it there in a controlled manner and to drop it along a linear guide onto a test specimen or impact surface. The resulting short-term impact makes it possible to assess how energy is absorbed by materials, designs, components and structures in the event of a crash and which (low and high frequency) crash signals are generated.

Equipment

- Drop height: max. 6.5 m

- Drop weight: max. 500 kg

- Max. impact energy: approx. 32 kJ

- Free fall speed: approx. 10 m/s

- baffle surface: 2500 mm x 2500 mm

- Test piece weight: max. 1000 kg

- sprung foundation: 20 t

- Optical deformation measurement with ARAMIS

- High-Speed Impact Cannon

- Device for pre-acceleration

- Temperature control chamber

Examples of use

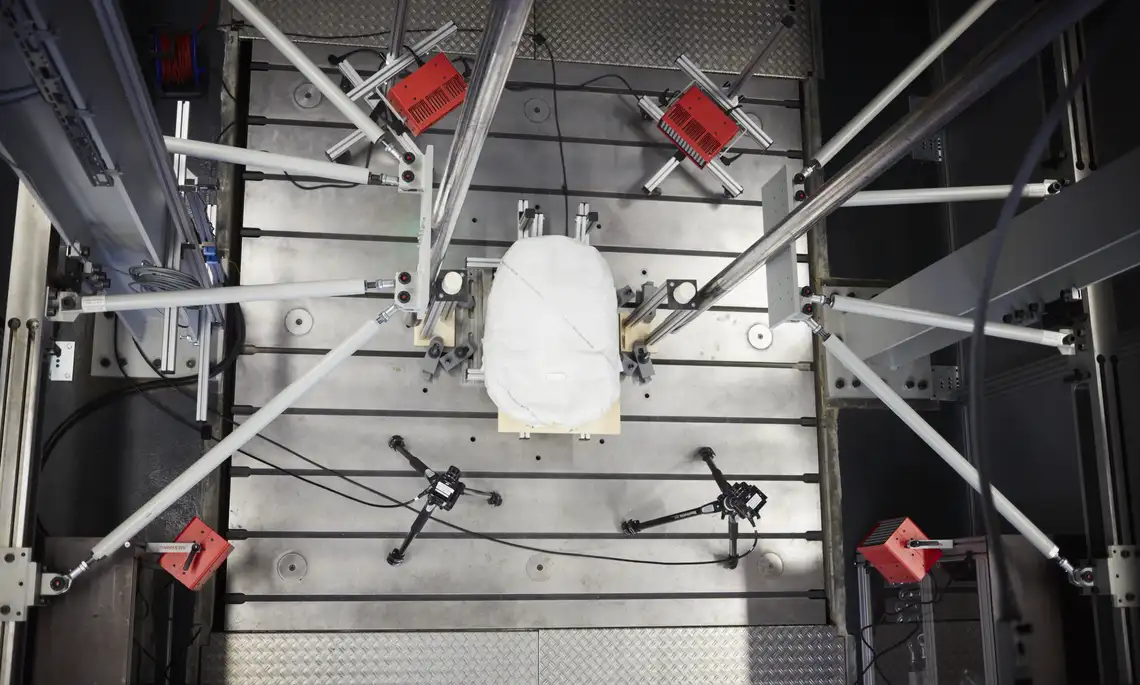

Crash tests on B-pillars

Energy absorption capacity and deformation characteristics of crash boxes

Validation of simulation results

Failure description of joined components

Laboratory management and team

Prof. Dr.-Ing. Christian Birkner

Phone: +49 841 9348-3404

Room: A112

E-Mail: Christian.Birkner@thi.de

Prof. Dr.-Ing. Thomas Brandmeier

Phone: +49 841 9348-3840

Room: H023

E-Mail: Thomas.Brandmeier@thi.de

Tobias Trabert, M.Sc.

Phone: +49 841 9348-3843

Room: H121

E-Mail: Tobias.Trabert@carissma.eu

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)